Power plants, refineries, chemical plants and all manner of oil and gas production facilities lost power in February of 2021. Organizations like ERCOT, The Texas Railroad Commission, Texas PUC and The Texas Oil and Gas Association all chipped in with advice on how to avoid those outages again. Some of those recommendations included: Some examples of preparedness suggestions can be found on each site:

Texas Public Utilities Commission:

Recommends that plant maintenance personnel fix failed equipment, and be sure that past solutions are “adequately” installed.

Texas Railroad Commission:

Has designated some midstream companies and certain critical feed points as vital. No specific suggestions on how to keep running if they freeze though…

ERCOT:

For many years ERCOT has put on workshops for power plant maintenance teams in the winter season. Hosted every September, their winterization workshops have been well attended. ERCOT has also sent their personnel on random plant audits through the fall to check and see how well plants were prepared. One example here from a 2015 workshop.

TXOGA

More recently, the Texas Oil and Gas Association has stepped in to encourage it’s midstream members to really give it their best and prepare for the winter with a set of ideas and suggestions on how they could best be prepared for the winter and stay on line:

And though many of these recommendations are solid in theory, when it comes to thermal protection- the issue shutting most plants down – the advice caused a major strain on supply chain channels.

Plant maintenance personnel, facilities engineers and supply chain workers were then tasked with finding some of the most unavailable commodities around-

Labor- it is well known that skilled workers are in short supply. Contractors tasked with building scaffolding and installing tarps around them are generally insulation contractors. If an insulation contractor has a chance to do an insulation job, or a scaffolding/tarp job…they would rather take the insulation job. When insulation workers are in short supply- business owners have to make the decision that is most profitable to them.

Hundreds of labor hours are used in each facility type for the plants listed above. Hours to procure the equipment, hours and freight to ship it to the site, hours to install the product once it gets there…and hours to fix it if it breaks.

Scaffolding and tarps- similar to the theory above, if you have a piece of scaffolding that can go out on 4-5 jobs over a 5-6 month period, and make money each time…vs leaving it on site to hold up some tarp- you’d rather do the 4-5x turn. Tarps are for sale and are not normally leased out like scaffolding- but the issues of getting them along with the cost involved in procuring, shipping and installing them- for a use that doesn’t really work anyway- is expensive and taxes an already stressed procurement group.

Supply chain and labor issues are well known, and they continue to persist as shown in this recent D Magazine article.

Supply Chain and Labor Shortage issues solved

Temporary enclosures, walls or “hooches”, as they are called at the plant, are one of the biggest problems when it comes to freeze ups- they just do not work. So why spend the time, resources and money on them? The Most common answer is compliance. The organizations that can fine us tell us we need to do it that way.

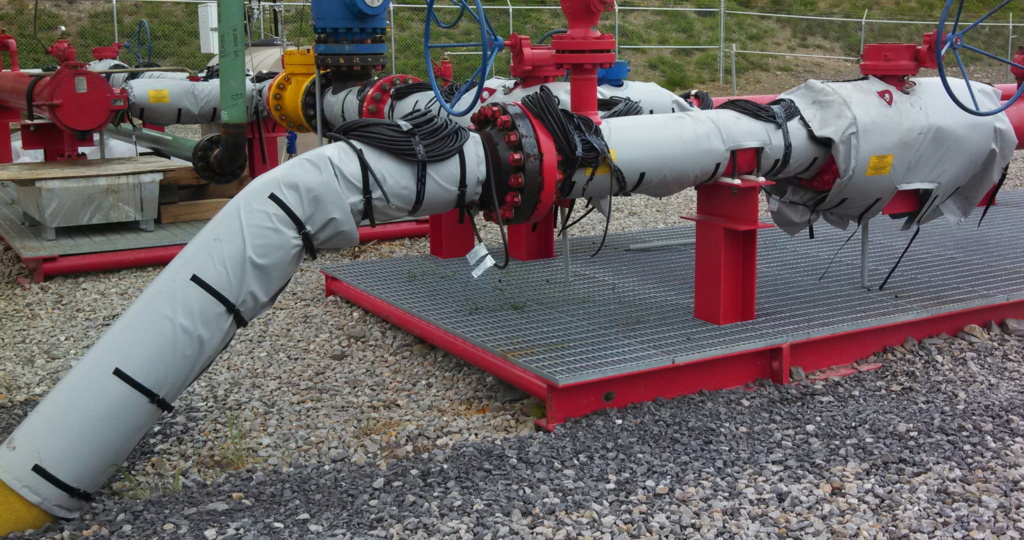

When you get right down to it, these solutions are offered to protect critical valves, actuators, tanks, transmitter manifolds, pumps, pipes and tubing from freezing.

Current industry offerings designed to freeze protect these components have not worked for many years.

There is no longer any need to build ineffective and dangerous tarps around critical non-heat traced components. Recently developed product offerings for heating valves, transmitters, pumps, pipes and many other components offer solutions to these problems that have never been offered before.

Powerblanket Hot Boxes integrate heat and Class 1 Division 2 rated safety, and can be made to fit a wide variety of sizes:

Powerblanket Valve and Transmitter Box Heaters can fit right over key valves and actuator systems to keep that valve control performing throughout that cold winter snap:

Dozens of other possible sizes and configurations can be created exactly for your application.

Heaters by Powerblanket can be designed to run on either 120,208 or 240 volts ac and can maintain up to 180 F while being exposed to up to 400F.

Powerblankets are 100% made in the USA in Salt Lake City, Utah. 100% customizable and can be rated for use in Class 1 Division 2 areas. Safe, effective and fit to your application.

Curious to see how Powerblanket can meet the unique needs of your industry?