When it comes to curing, Powerblanket helps its customers do more with less. That is, we help you accomplish greater cures and shorter curing times without relying on traditional methods for post-curing assistance. Powerblanket can help you increase your throughput without substantially increasing production costs.

Epoxy Applications

Manufacturers are finding more and more uses for epoxy each year. Let’s take a closer look at some of the most common epoxy resin applications.

Aerospace

Back in 1947, Howard Hughes used epoxies to construct his famous “Spruce Goose.” He assembled the enormous timbered aircraft with 3 layers of epoxy on it’s distinctive wooden frame. Epoxy and the aerospace industry have been inseparable ever since. In the world of today, aerospace manufacturers use epoxy resins to create aircraft skins, bond materials together, and make anti-corrosion coatings. Engineers are finding more and more ways to use composite fiber materials to make aircraft lighter. As composite fiber use increases, so does the demand for epoxy resins.

Wind Turbine Repair

As the world turns to alternative forms of energy, wind turbines are becoming a more common sight. Turbine blades are constantly exposed to the elements and eventually are in need of repair. These repairs are due to bird strikes, sand blasting, lightning strikes, salt corrosion, hail, ice, rain, and insects. Pitting and erosion on the surface of the blade ruin a turbine’s aerodynamic efficiency. Addressing these defects increases the turbine’s energy productivity. Due to the immense size and location of these blades, these epoxy repairs must be completed on site.

Skilled turbine repair technicians either build a platform to reach the blades or repel from above to accomplish repairs. Epoxy curing out in the elements is very difficult. Heating and protecting epoxy patches during curing is absolutely critical in outdoor wind turbine repair.

Flooring

Epoxy flooring is installed in both residential and commercial buildings. High traffic areas (pedestrian or vehicular traffic) like garages, walkways, loading docks, and game courts commonly use epoxy flooring. Epoxy flooring is extremely strong and seals and protects concrete sub-grade from a variety of structural and visual defects.

Furniture and Decor

Epoxy is continually crossing over from function to form as its uses expand into furniture and decor. Epoxy resin inlays and molds can create an infinite number of projects like intricate custom tables, counters, and other home accents. Proper curing for decorative epoxy is absolutely critical because any discoloration or deformity will greatly affect the finish product.

Marine Epoxy

Because epoxy creates a waterproof seal, it is ideally suited for maritime applications. Epoxy saturated wood efficiently keeps moisture out. Epoxy is also used as an adhesive to bond materials together and to create an anti-corrosion coating.

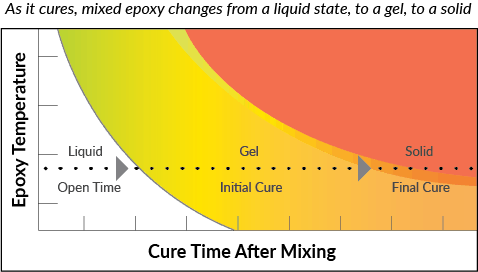

The Science of Curing

Whether you cure epoxy or resins for wind-turbine blades, aircraft wings, flooring, carbon-fiber construction, or some other similar composite-manufacturing application, you know that a proper cure takes time.

Open Time

The initial epoxy curing stage is referred to as “open time.” During this period, the epoxy is liquid, workable, and easily formed. If epoxy is manipulated after the open time has passed, it will not properly bond with the surface it is being applied to.

Initial Cure

In this second stage, the chemical reaction of curing begins to kick off. It becomes tacky, gel like, and is no longer workable. Applying moderate heat during this stage greatly shortens the overall cure time.

Final Cure

Here, the epoxy is hard and has reached about 90% of its cure strength. If left at room temperature, the epoxy could still take weeks to fully cure to 100%.

Curing Heating Methods

Curing is an exothermic process. When epoxy is confined to a small area (like a mold), it generates enough heat to cure quickly. However when poured, rolled, or spread in thin coats over a large area, it takes much longer to cure. Using safely applied heat during this process can greatly speed up your epoxy cure.

In any industry, time is money. Waiting long periods for epoxy to cure at room temperature jeopardizes project schedules and your bottom line. Some manufacturers turn to heating methods to speed up their cure times and achieve a stronger cure.

Curing Chambers

Manufacturers in the aerospace and maritime industries will sometimes construct or purchase large heated enclosures. These enclosures house aircraft and marine craft sections to speed up epoxy curing. These chambers can be extremely expensive and take up a lot of space on the factory floor. Constructing these chambers also requires a great deal of time and manpower.

Heat Guns/Lamps

For more reasonably sized epoxy applications, some turn to heat guns and lamps to speed up curing. However this heating method does not supply controlled or evenly distributed heat. Some areas will become hotter than others and curing will not happen evenly. You also run a greater risk of overheating sections of your epoxy. Overheating epoxy can cause materials to melt, smoke, or burn. It will also create dangerous fumes and unpleasant surface defects.

Outdoor Epoxy Repairs

Controlling curing conditions in a factory or warehouse is one hurdle when working with epoxy. However, outdoor repair jobs on airfields, wind farms, and marinas presents an entirely new set of problems. How do you protect your epoxy from the elements and ensure a quick strong cure?

Powerblanket Curing Solutions

Powerblanket produces a line of products specifically designed to increase efficiency and decrease curing time. Powerblanket resin curing blankets can provide heat up to 180° F to assist in both initial cures or post cures. Applying safe heat to your curing process enables resin to cure faster, decreasing the time it takes to move from one step of manufacturing to another. What’s more, when using a Powerblanket curing solution, you don’t have to throw money into costly curing ovens any more.

Our curing blankets are portable and easy to install, making them the perfect solution for epoxy repairs out in the field. With heavy duty, weather resistant insulation and evenly distributed heat, you can cure quickly and completely no matter what mother nature throws at you.

Curing doesn’t have to take as long or cost as much as it does traditionally. Contact us today to find the right curing solution for your needs at 844.455.3210 or [email protected].

Cure your epoxy resins faster and easier than ever before with Powerblanket.