How Warm Does it Have To Be To Pour Concrete?

Whether the conditions are hot or freezing, the ideal concrete curing temperature should be maintained at about 55°F to achieve the optimum concrete strength.

Curing the Hoover Dam

At its completion in 1935, the Hoover Dam was the largest dam in the world and a marvel of labor and engineering. The first pour began on June 6, 1933. Rather than being a single block of concrete, workers built the dam as a series of individual columns. The trapezoidal columns rose in five foot lifts. This method allowed the tremendous heat produced by the curing concrete to dissipate. If the dam were built in a single continuous pour, the concrete would have gotten so hot that it would have taken 125 years for the concrete to cool to ambient temperatures. The resulting stresses would have caused the dam to crack and crumble away.

The heat and dryness of Nevada posed additional complex problems with the pour and concrete curing temperature. When the concrete was first poured, river water circulated through cooling coils of 1″ thin-walled steel pipes. Once the concrete had received a first initial cooling, chilled water from a refrigeration plant on the lower cofferdam circulated through the coils to finish the cooling.

Concrete Curing is an Art

We live in a world where faster always seems better; however, concrete that cures too quickly or under hot concrete curing conditions can actually result in weak or unstable concrete. If concrete is cured in cooler ambient temperatures (32°F to 50°F) with moisture continually present, strength gain will be slow but the concrete will eventually reach a high strength. Concrete should not be allowed to get hotter than 90°F or to dry out during the curing period.

Speed up your concrete curing with the Powerblanket system. Our patented technology allows you to cure concrete up to 2.8 times faster, even in cold conditions. Our concrete curing blankets maintain proper moisture levels throughout the concrete hydration process. This prevents common issues like surface cracking and inconsistent strength.

Best Concrete Curing Temperature

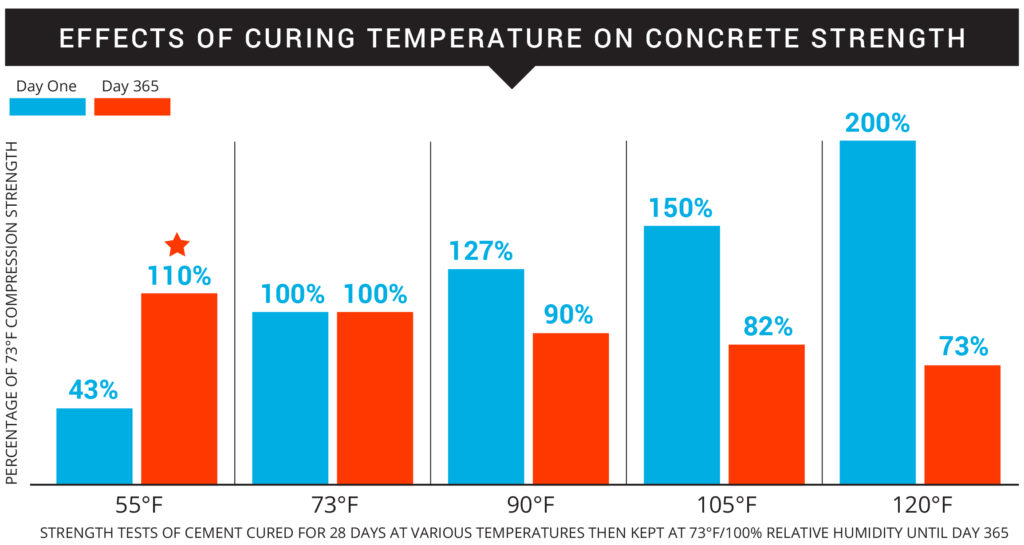

By “best” we mean “most thoroughly,” not the fastest. High temperatures mean faster curing, but fast curing equates to weaker strength in the end. The following study by Paul Klieger in the Portland Cement Association Research Bulletin 103 illustrates this concept.

Concrete Cure Time Chart with Temperature

At an age of 1 day the 120°F concrete was strongest and the 25°F concrete was weakest. By 7 days the high-temperature cured concretes had no more strength than the 73°F concrete or even less. By the age of 28 days the high-temperature concretes were weaker than the 73°F concrete. From 28 days to 1 year the 55°F concrete was considerably stronger than the 73°F concrete. All of this suggests that, provided there is continuous curing, concrete cured at about 55°F for the first 28 days ultimately reaches the highest strength (Concrete).

Hot Weather Concrete Temperature Limits

Hot weather concreting doesn’t simply involve temperature. High ambient temperatures, winds, and relative humidity all play a role in “hot weather.” Under hot heather conditions, the primary curing issue is having the top of the slab of concrete dry much faster than the bottom. As concrete dries it shrinks. This means that the top will be shrinking while the bottom is not. This creates internal problems with the concrete that will result in a damaged slab. The top and the bottom of the pour need to cure at the same rate (Placing).

Concrete Curing Temperature Solutions

Is it too HOT?

North Slope Chillers makes portable cooling equipment that will keep newly poured concrete safe from heat. Portable, insulated, and efficient, North Slope Chillers effectively regulates the temperature of concrete under both regular and hot conditions.

The Fluxwrap Circulation Blanket is combined with either a cooler or chiller to achieve optimum results. The Circulation Blanket draws heat to the blanket in order to cool the concrete.

- Use Powerblanket’s patented heat-spreading technology in reverse–the cooling blanket draws heat away and lowers the temperature of the concrete.

- Blanket cover and insulation are the same as the robust system used in Powerblanket heating products

- Portable

- Control the curing speed of newly poured concrete even in hot conditions

Is it too COLD?

Can you pour and cure concrete in the winter? Powerblanket concrete curing blankets provide a manageable way to cure concrete effectively and confidently in the cold weather months. Even in warm weather, Powerblanket curing blankets increase production by rapidly curing with consistent, even heat.

- Cure concrete 2.8 times faster than conventional, insulated blankets

- Produce cold weather concreting strength of up to 3,925 psi in 72 hours

- Maintain moisture throughout hydrating process

- Easily installed and removed

- Prevent a freeze cycle

- Thaw ground and frost from job site prior to pour

- Reduce downtime & increase profitability

- Maintain ACI compliance for cold weather concreting

Powerblanket understands what it’s like to work on large concrete projects when the weather and temperatures aren’t cooperating. From the Statue of Liberty to a major interstate bridge in Kansas City, we’ve been a part of the action and have proven our products to be the best in the industry.

For more info on solutions, check out Powerblanket’s Concrete Curing Blankets and find one that fits your needs best.

Works Cited

“Placing Concrete in hot or cold weather”. Sakrete Blog. 16 May 2017. https://www.sakrete.com/blog/placing-concrete-in-hot-or-cold-weather

“The Story of Hoover Dam – Essays”. Bureau of Reclamation. 16 May 2017. https://www.usbr.gov/lc/hooverdam/history/essays/concrete.html

Frequently Asked Questions

What is the best temperature for concrete to cure?

The best temperature for concrete to cure is between 50 and 70 degrees Fahrenheit, as this range supports the optimal chemical reactions needed for concrete to gain strength effectively.

Can you pour concrete if it freezes at night?

Pouring concrete when it freezes at night is not advisable, as the concrete should not freeze within the first 24 hours; using thermal blankets can help prevent frost from forming.

How long does it take for a 4 inch concrete slab to cure?

A 4-inch concrete slab typically takes 28 days to fully cure, although it can support foot traffic after 24 to 48 hours and vehicle traffic after 7 days.

What is the lowest temperature you can lay concrete at?

The lowest temperature for laying concrete is above 40 degrees Fahrenheit, as temperatures below this can negatively affect the hydration process and the concrete's strength.

Cure your concrete faster and better in cold weather conditions with Powerblanket.