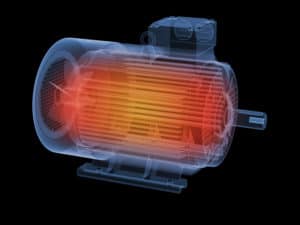

If you run electric motors consistently, you know overheating poses a substantial problem to your motor’s life expectancy and the continuity of your operations. However, this is a problem you won’t need to worry about any longer. North Slope Chillers cooling systems can keep your motors running at the best temperature, offering the perfect electric motor cooling solution.

Thermal Stress On Electric Motors

Many industries use electric motors for a wide range of applications. They fuel much of the conveniences we enjoy on a daily basis. When it comes to industrial applications, they are an important tool for your business success. Yet the stark reality is, there isn’t an electric motor out there that’s totally fail proof.

Actually, one of the most common causes of electric motor failure is overheating. When your motors experience thermal stress, the windings suffer insulation deterioration. To put this in numbers, your motor’s insulation life decreases by 50% for every 50 °F (10° C) increase in heat. So, if you don’t have a cooling plan in place for your electric motors, you’re going to experience significant setbacks.

Cooling Precautions

Taking certain steps can protect your electric motor from normal levels of thermal stress deterioration.

Right Motor For The Right Job

Motor vehicles need engines that are correctly sized and powered for each application. Industrial motors are no different. Make sure your selected motor has the correct power output and energy usage for your operation.

Give It A Good Home

Some thermal stress can be avoided by mounting electric motors in the correct location. Ensure your motor has access to proper air-flow so it can enjoy normal levels of heat dissipation. Some motors are installed in locations where they need housing enclosures to dampen noise. If this is the case, your enclosure needs to have proper ventilation to prevent overheating.

Liquid or Air Cooling

There are 2 main ways to keep an electric motor from overheating: liquid cooling or air cooling.

Air Cooling

Air cooling involves fan forced air flowing over the hot motor to dissipate heat into the ambient air. For some applications, flowing room temperature air over the motor may be sufficient. For other applications, chilled air may be required to reduce the motor’s thermal stress.

Liquid Cooling

Depending upon the motor’s workload, length of time being used, housing, and location, air cooling may not be enough. Some industrial motors require chilled liquid coolants to remove enough heat to keep your operation running.

North Slope Chillers Motor Cooling Solutions

The good news is that Powerblanket has innovative process cooling solutions that prevent overheating in electric motors. Our partner, North Slope Chillers, is well equipped with industrial motor cooling options. Our expansive line of industrial chillers are portable, easy to install and won’t disrupt the layout of your current system. In addition, North Slope Chillers offers a range of cooling capacities from 85° F all the way down to -112° F.

Benefits of North Slope Chillers:

- Protect your motors against overheating and avoid damaging valuable assets

- Increase motor efficiency, operational efficiency, and profit

- Avoid costly downtime caused by over-heating shut downs

Custom Cooling for Electric Motors

The breadth and variability among electric motors can make it difficult to know what cooling solution you need. Because of this, we proudly offer the quickest custom order lead time on the market. Our customization process is as easy as 1, 2, 3…

- Our world class engineering team learns your needs

- Your custom quote is available in 1-3 days

- We ship your custom chilling solution in 1-3 weeks

Contact us today at 844.903.1837 or [email protected], and we’ll help you prolong their life and keep your operation running.

Frequently Asked Questions

How do you cool down an electric motor?

Electric motors can be cooled down by using forced air cooling, where an electric fan blows air over the motor to dissipate heat, or by employing liquid cooling systems that circulate chilled liquid to absorb excess heat.

What type of cooling is in an electric motor?

Electric motors can utilize various cooling systems, including air cooling, liquid cooling, heat pipes, and hybrid systems that combine heat pipes with liquid cooling to efficiently manage motor temperatures.

What keeps an electric motor cool?

An electric motor is kept cool by its frame or casing, which often features cooling fins to enhance heat dissipation, and by fans that blow air across the motor to increase heat transfer from the motor to the surrounding air.

Do electric motors need coolant?

Yes, electric motors, especially in high-demand applications, may require coolant to effectively manage heat and prevent overheating, ensuring optimal performance and longevity.

Keep your products and processes within the desired temperature range with Powerblanket's industrial cooling solutions.