Cold Weather Epoxy

Anyone who’s worked with epoxy knows that cold weather epoxy is a difficult mixture. So what do you do to protect your epoxy when cold weather hits?

How Do Cold Temperatures Affect Epoxy?

Curing Time

Frigid temperatures slow down curing times for epoxy resin. If you are looking for a longer working time, this could be advantageous, but it also means that the project will take an extended amount of time to complete.

Product Viscosity

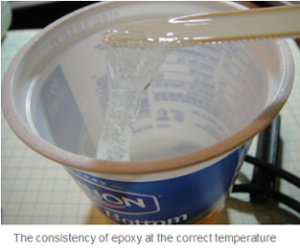

Cold weather epoxy applications do not flow as smoothly. The product will be much thicker than usual to pour and mix. If the product or surface is too cold, a self-leveling epoxy may not level properly and leave divots or fish eyes.

Humidity Problems

When working in colder temperatures, increased humidity in the atmosphere may also affect the project. Moisture may settle on the uncured epoxy and lead to blushing, surface defects, or a flat finish.

Epoxy’s Happy Place: 60°F-85°F

For most epoxies, 60°F-85°F is the ideal range for operation and storage. If epoxy drops below this, it could drastically affect its characteristics, as shown above. For successful application, keep epoxy from falling below this mark, which is not always easy. To maintain 60°F 85°F for your epoxy means that the surrounding temperature cannot be less than 60°F.

Bring Epoxy Resin Into the Temperature Threshold Before Working With It

Raise Ambient Temperatures to 60°F-85°F

Raise the workspace temperature quickly with small space heaters with thermostats. Some thermostats may not be 100% accurate, so it is best to set the temperature to a few degrees warmer to ensure the correct temperature is met.

Keep Epoxy Resin at the Ideal Temperature During the Cure

Ensure that the project stays at the right temperature during the entire curing process, which is an average of 72 hours. The project will most likely feel hard to touch after 12 hours, but it is very important to protect against cold temperatures for 72 hours.

A Cold Weather Epoxy Solution

With Powerblanket’s patented heating technology, you don’t have to worry about these common dilemmas any more. Powerblanket’s barrel, drum, and bucket covers allow you to heat your epoxy storage to the ideal temperature in very economical way.

Effective industrial drum heaters eliminate waste and lower costs incurred from materials damaged by improper storage. Epoxy stored in drums and barrels have strict temperature requirements. It’s important to store these products at optimal temperatures. Using a Powerblanket as part of your epoxy system will prevent wasted/damaged product, inflated costs, and lost time.

Powerblanket’s 55 gallon drum heater, 30 gallon drum heater, and 15 gallon drum heater blankets all come with temperature control options for optimal results. Unlike conventional insulated blankets and band heaters, Powerblanket has developed the best heat distribution solutions to heat barrels and drums evenly and consistently. Maintain optimal viscosity and flow, while avoiding a premature cure in the barrel. Using a Powerblanket drum/bucket heater allows you to keep epoxy at the desired application temperature. The warehouse may be cold, the work area may have a draft, but with Powerblanket the product will always be ready for application.

Powerblanket also manufactures blankets specifically for epoxy curing. Protect your cure and read optimal cure strength with Powerblanket. Learn more about epoxy curing blankets here.

See for yourself the benefits of Powerblanket as compared to band heaters by downloading our free case study. For further questions about Powerblanket’s epoxy curing solutions, call 877.626.5233 or visit [email protected].

Powerblanket's industrial drum & barrel heaters provide even and consistent heating, eliminating waste and lowering costs.