The Nature of Spray Foam

To put it simply, spray foam just doesn’t work in cold weather. Polyurethane foam is very sensitive to temperature in its liquid state. The preferable temperature of application is between 60-80° F. However, construction doesn’t stop when the thermometer drops well below 60º.

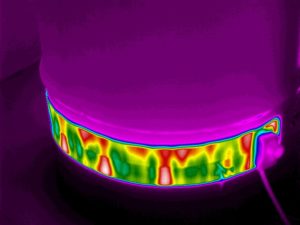

The cold-weather dilemma is nothing new to the world of spray foam. Winter application has been a challenge for as long as SPF has been around. In fact, in the past, some professionals tried using band heaters on their totes in order to keep the foam warm enough for application. However, this caused more problems than it solved. Band heaters give off patchy warmth, leaving lumpy, unevenly heated spray foam.

Ba(n)d Heaters

Some professionals have tried using band heaters to keep their spray foam warm during cold-weather application. The problem is that band heaters offer inconsistent and unregulated heat, causing burning and charring of the product.

Insulated Heating Blankets

Insulated blankets offer a solution that is much more efficient and safe than band heaters. They provide even heat distribution over the entire container. The temperature is completely regulated, especially if you get an external remote, keeping your spray foam at the ideal temperature for cold weather application. You don’t have to worry about burnt product, uneven heating, or damage to equipment. Powerblanket’s spray foam heaters were designed with spray-foam application in mind, making them the perfect answer to your wintertime woes.

Stand Out Feature of Powerblanket Spray Foam Heaters

Stand Out Feature of Powerblanket Spray Foam Heaters

- Evenly heats spray foam from all sides for a consistent performance

- Consistent and regulated heat distribution protects against burning and scorching

- Well-insulated unit keeps the heat from leaking out

- Safety certifications, including a UL listing (in the U.S.) and CSA (in Canada).

Keep your business running smoothly through the cold winter months with Powerblanket spray foam heaters.