The railroad industry takes a beating all winter long. We rely upon trains to keep cargo and passengers moving day after day through rain, sleet, hail, and snow. However, even though we demand rail continuity, extreme temperatures and weather can take a real toll on the equipment and materials needed to keep trains moving. How does the railroad industry cope with the demand during winter conditions? Let’s take a closer look at some of the railroad heating solutions used today.

Ice and Snow Clearing

Ice and snow can build up in a number of different rail locations. Freeze-thaw cycles, freezing rain, snow accumulation, ice storms, and burst pipes can create ice buildup on both horizontal and vertical surfaces. Many different track sections are impaired by ice buildup such as: safety sensors, wayside/defect/drag detectors, track curves, track switches, crossing gates, safety signals, and more. Therefore, ice and snow clearing is one of the most critical railroad heating solutions needed during the winter.

Air Blowers

Gas or electric powered air blowers are a common solution for clearing ice and snow. These heaters blow forced hot air over vulnerable sections of track, such as switch points. The hot air not only melts ice blockages but also drives the melted moisture away so it cannot pool and re-freeze.

Other Switch Heaters

Some switch heaters heat using conduction. Electric track switch heaters can also be placed directly on the rail to transfer heat via metal blades, tubes, or plates. Gas switch heaters can also run fuel lines along the track itself and use a series of small flames to melt ice and snow. Both types of gas heaters rely upon on-site gas cylinders storing either propane or natural gas.

Wedge Plows

During winter months, rail companies can also fit their engines with wedge plows. These specialized cars are perfectly shaped for breaking apart snow and ice dams and driving them to the sides of the tracks. Although wedge plows are not technically a railroad heating solution, they can be very instrumental in areas that see large amounts of snow accumulation.

Heating Blankets

When ground heave and ice blockages damage sections of rail, repairs often cannot wait until warmer weather. Frozen ground can be almost impossible to penetrate during these repair sessions. Ground heating blankets can be used to thaw frozen ground in order to excavate, level, and grade ground before repairing a damaged track.

Lubricant and Grease Heating

Of all the liquids one might store in the winter time, oil and grease brave the cold better than most. Both have an extremely low freezing temperature, and they can be stored in many different ways. However, this doesn’t mean that cold weather can’t affect oil and grease. Lubricants need more than just freeze protection, they need viscosity solutions.

Heating Blankets And Enclosures

Because liquids become thicker and more viscous as temperatures drop, they can become completely unusable during cold weather. In order to pump, spray, spread, or work with railroad lubricants during the winter, heating solutions are needed. Whether railroad companies use flange oilers, oiler cars, or mobile grease trucks, grease and other lubricants must be kept at workable temperatures.

Grease storage containers cannot always be kept in a climate controlled facility so they are warm and workable. Most railroad lubricant buckets and drums are stored wayside, on oiler cars, or on mobile grease trucks that patrol sections of rail. Because these lubricant containers are out in the elements, they need heated blankets or enclosures to keep grease warm while on the go.

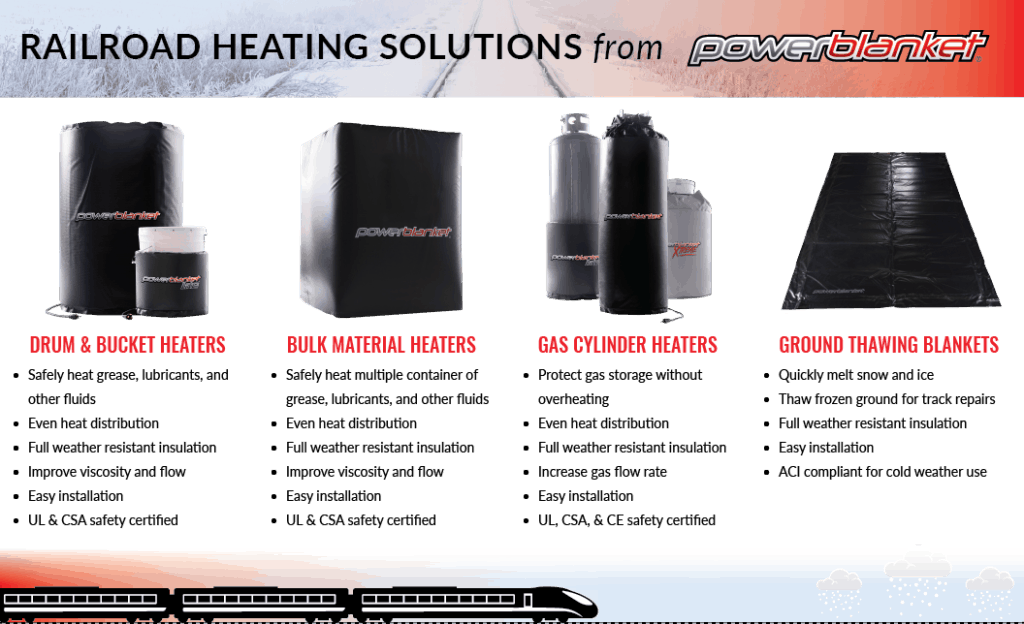

Powerblanket Railroad Heating Solutions

Powerblanket specializes in highly efficient railroad heating solutions. We provide safe and even heating for equipment and materials that keep operations running all winter long.

Gas Cylinder Heaters

Powerblanket’s gas cylinder heaters are perfectly suited for on-site gas heating fuel storage. Low temperatures cause pressure within rail-side storage tanks to drop dramatically. As a result, these low-pressure tanks cannot reliably power gas track switch heaters. Fortunately, our gas cylinder heaters provide safe, even heat to railroad gas storage in even the coldest of conditions. Heavy-duty, weather resistant insulation also adds an extra level of protection during the long cold winter months. In addition, our gas cylinder heaters are UL, CSA, & CE safety certified with additional hazardous location certifications available.

Ground Thawing Blankets

Preparing frozen ground for track repairs is a breeze with Powerblanket’s high heat ground thawing blankets. Our blankets drive deeply penetrating heat where it is needed most, and remove frozen obstacles all down the rail. Powerblanket can save yourself from costly downtime and help you complete track repairs all winter long.

Hot Boxes

Powerblanket’s bulk material warmers are the perfect railroad heating solution for multiple containers of varying shapes and sizes. Our hot boxes eliminate hot and cold spots and evenly distribute heat to all materials and equipment housed inside. Because our bulk material warmers are easily portable, they can provide heating during storage and transportation.

Drum and Bucket Heaters

We know cold temperatures make industrial fluids impossible to work with. That’s why Powerblanket’s drum and bucket heaters are the perfect solution for railroad grease and lubricants. Solve your viscosity issues and safely heat railroad lubricant storage containers and keep them at workable temperatures.

All in all we are proud to offer solutions that get the railroad industry back on track, no matter what winter throws your way. Contact Powerblanket today to find the perfect railroad heating solutions for your needs at 877-626-5233 or [email protected].

Curious to see how Powerblanket can meet the unique needs of your industry?