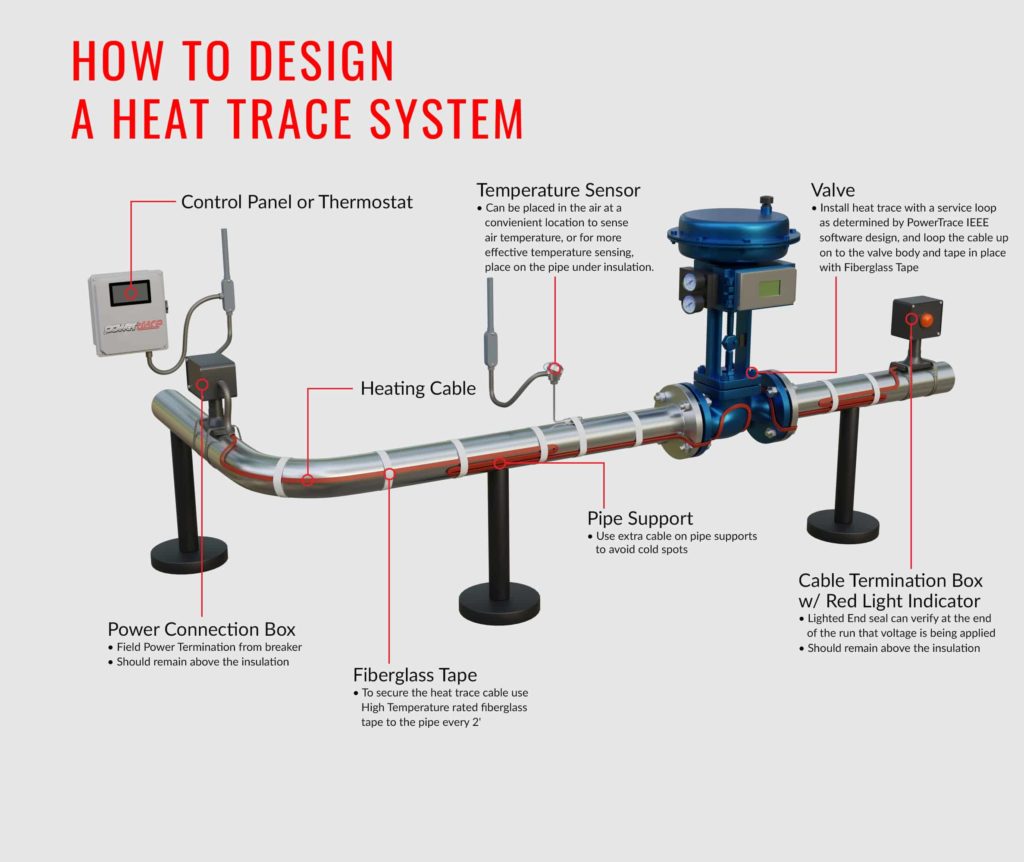

What is electric heater cable?

Electric heater cables are wired cables that produce heat, commonly called heat tracing cables or heat trace. Heat tracing cables can be used for a wide range of applications within the home, around the construction site, or along lengths of pipeline.

What are the different types of electrical heating wires?

There are two main types of electrical heating cables used in process heating. These include:

- Heating cable (also known as heat tracing or heat trace systems)

- Heat tape

We’re going to talk about heat tracing cable in this blog post. Heat tracing cable can be split into two main products: self-regulating heating cable and constant wattage heating cable.

Powerblanket’s self-regulating heat trace cable provides customizable temperature regulation across your system. Its adaptability allows it to be used in many applications while ensuring safety and reliability. Invest now for long-term savings from reduced system failures.

What is self-regulating heating cable?

Self-regulating heat tracing cable is simply heat trace that has the ability of adjusting the power output of electricity along its entire length of cable. For example, some parts of the heat trace cable might self-adjust to different temperatures that are different than other parts of the cable.

Self-Regulating vs. Constant Wattage Heat Tracing Cables

Both types of electrical power supplies can serve exactly the same purposes, although the application will usually determine the best solution to the problem. Self-regulating can change in temperature via adjustable power throughout the cable. Constant wattage does not have that ability, but instead pushes a constant stream of power through the cable to ensure even distribution of heat.

How Does Constant Wattage Heat Cable Work?

Constant wattage heat trace cable provides consistent, even heat at a preset temperature along the entire line of heat trace. It is called “constant wattage” because it has the same wattage per linear foot throughout the line of cable.

Using self-regulating heat tracing effectively

Self-regulating heat tracing can be an effective part of your organization’s process heating plan. It is best used in situations when external temperatures fluctuate based on changes in the environment. For example, climates that have cold nights and warm days are great for self-regulating heat trace because the cable will automatically turn on when temperatures drop below a preset threshold at night and turn off once it warms up during the day.

Self-regulating heat trace cable has many additional benefits for battling cold temperatures. For more information, including how to install heat trace, read up on everything you need to know about heat trace.

FAQs about self-regulating heat tracing cable:

Does self-regulating heat trace cable need a thermostat?

Yes, as a thermostat will be able to tell the self-regulating heat trace cable what temperatures to adjust to. Many self-regulating heat trace cable products come with an internal thermostat, but check with the seller just in case to make sure your cable has everything needed to work right out of the box.

What temperature does self-regulating heat trace work best at?

Self-regulating heat trace usually turns on automatically when descending temperatures near freezing (30°F to 40°F).

Can you leave heat trace plugged in?

Yes. Most heat trace products come with internal thermostats that regulate how hot the wire will get, which prevents overheating.

Can you leave heat tape plugged in?

Yes, but only if it is using a built-in thermostat to monitor how hot it gets. Heat tape that is left plugged in without any kind of temperature regulator can lead to a dangerous workplace environment. Checking your heating equipment’s thermostats regularly should be a part of your organization’s safety plan.

Which is better, heat tape or heat cable?

As with self-regulating vs. constant wattage heating cables, it depends on the application. Heat cable doesn’t shrink, unlike heat tape, and it’s more durable in harsh conditions. Heat tape, however, is very flexible and is best used for contoured applications like pipes and hard-to-reach corners.

How do I know if I need self-regulating or constant wattage heating cable?

Not every heating application needs constant wattage heating cable, nor does every application require self-regulating heating cable. Self-regulating heating cable is often the best choice for ice buildup prevention on roofs and gutters, as well as for pipe freeze prevention. Constant wattage heating cable, on the other hand, is better suited for snow melting and indoor floor heating.

Can heat trace cable touch itself?

In nearly every circumstance, NO. Heat trace cable should not be allowed to touch or cross, as heat from the touching cables will cause the cables to burn through each other, leading to more damage. However, the thermostat within a self-regulating heat trace cable will react to the excess heat generated when cables cross and adjust accordingly. Thus, while it can technically be considered safe to touch itself, the general rule is to prevent heat trace cables from touching or crossing.

Self-regulating cables – Powerblanket heat tracing

Self-regulating heat trace cable is available from Powerblanket. It has the capability to regulate temperature at a wide range of levels on vessels, pipes, hoppers, and valves. Heat cables can be embedded into all sorts of applications to provide constant freeze protection.

Like all Powerblanket products, self-regulating heat trace cable is ETL certified to UL and CSA safety standards. Use Powerblanket heat trace to protect materials, ensure reliability of pipes and valves, and provide peace of mind for you and your employees. Contact Powerblanket at (844)-817-6105 or [email protected] for additional information on how self-regulating heat trace cable can be a part of your organization’s process heating plan.

Don't let the cold weather stop your business. Powertrace heat trace cable will keep you running smoothly no matter how low the temperatures.