We are now in or approaching the coldest time of the year. Perhaps you have noticed, not just because of how cold it feels, but because of your heating bills. If you are losing a lot of costs to heating, whether in your warehouse, shop, or in your own home, have you thought of improving your insulation? Let’s explore spray foam insulation vs fiberglass insulation.

What’s the Best?

Spray Foam Insulation vs. Fiberglass

Traditional insulation comes in primarily two forms: fiberglass or cellulose. Both products are better than not having any insulation at all (and they’ve been used in homes for a long time now), but by today’s standard, they simply don’t stand up to the far more efficient option of polyurethane spray foam.

Leaking Air

Up to 40% of a building’s energy is lost due to air infiltration. Infiltration is the unintentional or accidental introduction of outside air into a building. Cracks in the structure and entrance/exit doors are the primary culprits here. Infiltration is sometimes called air leakage. The leakage of room air out of a building, intentionally or not, is called exfiltration. Gaps and air leaks allow expensive heating and air conditioning to go to waste, conversely increasing energy bills. The U.S. Department of Energy estimates that 56% of a home’s energy is used for heating and cooling. An alternative to traditional cellulose and fiberglass insulation, spray foam insulation resists heat transfer and insulates and seals gaps. Spray foam creates a tight barrier and prevents air infiltration, and vapor and moisture from penetrating into a building’s interior. It can also be an effective a sound barrier.

Save Energy

Spray foam is extremely impermeable, which is why it acts so well as an insulation product. The Icynene® website (a leading brand of polyurethane spray foam) offers a helpful comparison. Spray foam works a lot like a wind breaker, or a good winter coat. It keeps the warmth in and the cold air out. Conversely, traditional insulation (fiberglass and cellulose) works more like a woolen sweater, Like a sweater, allowing air leakage that contributes to inefficient insulation. Spray polyurethane foam expands to insulate and fill cracks and gaps to provide a consistent air seal. According to the U.S. Department of Energy, using spray foam to minimize air leaks in walls and roofs, a typical homeowner could save up to 15% on heating and cooling costs.

The nature of foam however is entirely separate, keeping air both in and out of the insulated area. This of course is pertinent for both summer and winter. In the summer months you need good insulation to keep the cool air in and the hot air out. While fiberglass insulation is considerably cheaper than spray foam, the amount of money lost to heating and cooling costs from inefficiency are a much greater loss.

Where Is Spray Foam Useful?

Spray foam insulation can be used to seal areas that commonly involve air leaks, including:

- Attic hatches

- Plumbing vents

- Wiring holes

- Windows and doors

- Behind knee walls

- Basement rim joists

- Open soffits

- Recessed light, furnace flue or duct chaseways

Spray Foam Insulation vs Fiberglass

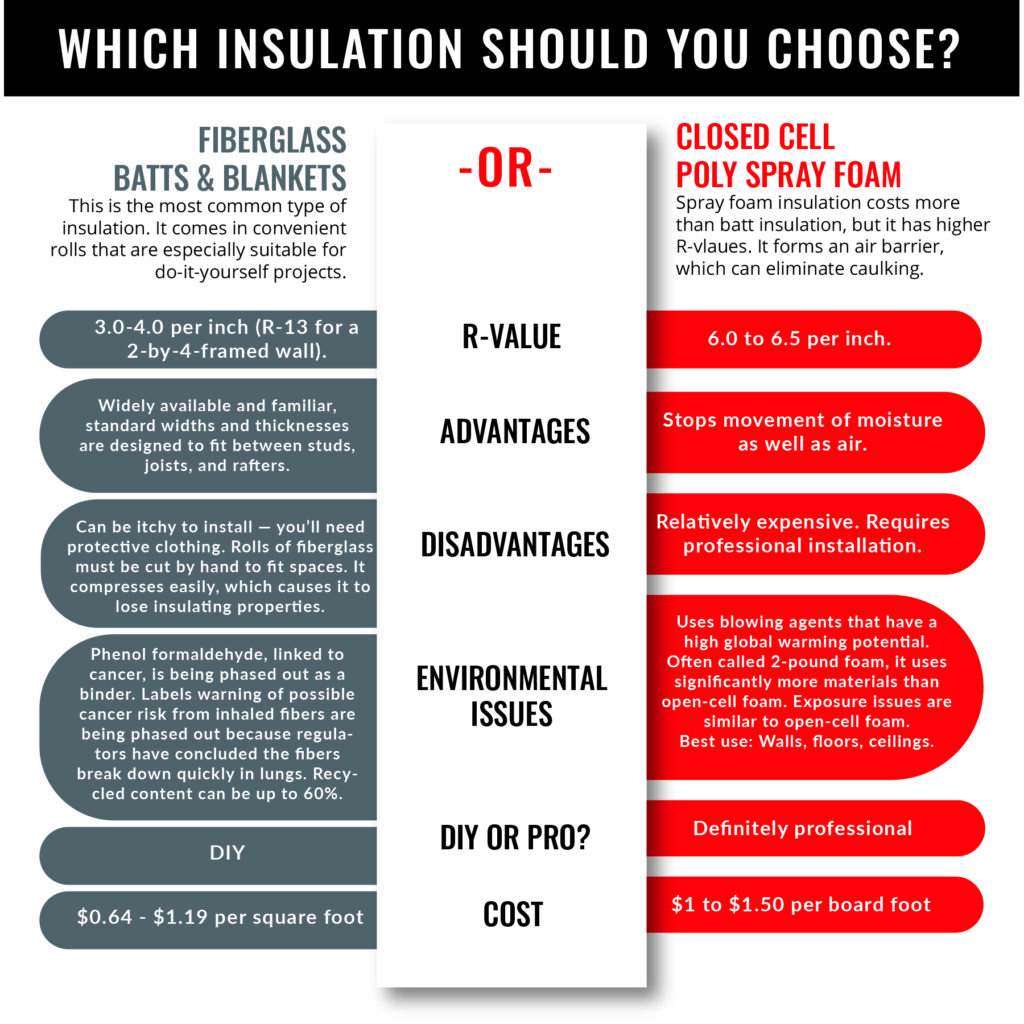

The following chart puts fiberglass and closed cell spray foam side by side in order to compare the strengths and weaknesses of both. While spray foam is more expensive and requires more effort to install, the overall insulation power is a strong advantage.

Powerblanket and Spray Foam

Powerblanket serves the spray foam industry with ready-to-ship and custom spray-foam heating solutions. Spray foam simply doesn’t work in cold temperatures, and this causes downtime and delayed projects. Some have tried to use band heaters in the past, but all it did was burn the product, which caused the foam to flake—clogging up equipment, pumps and hoses. In addition to this, band heaters are not durable and have unreliable thermostats. They can also cause inconsistencies in the application process. Locally over-heated foam reacts and expands in the tank, barrel, or cylinder and creates defective product, which in turn slows the flow rate and increases the problem of downtime and delayed projects.

However, with Powerblanket spray foam heating solutions, professionals can keep their spray foam at the ideal temperature with the risk of overheating or downtime. The Powerblanket solution allows for year-round application whether the weather is warm or cold.

Frequently Asked Questions

Why is it hard to sell a house with spray foam insulation?

Selling a house with spray foam insulation can be challenging because potential buyers may be concerned about the quality of installation and the potential for improper application, which could lead to issues like air sealing problems or moisture retention.

Is there a downside to spray foam insulation?

While spray foam insulation offers excellent thermal efficiency and air sealing, its downsides include higher initial costs, potential health concerns if not installed correctly, and challenges in obtaining a mortgage due to its complexity.

Where should you not use spray foam insulation?

Spray foam insulation should not be applied directly against electrical wiring or fixtures unless they are rated for contact with insulation, as this can pose a fire hazard.

What is the biggest problem with fiberglass insulation?

The biggest problem with fiberglass insulation is its tendency to trap moisture and allergens, which can lead to mold growth and negatively impact indoor air quality.

Keep your business running smoothly through the cold winter months with Powerblanket spray foam heaters.