Problems with the global supply chain are impacting nearly every business in America

What is the crisis?

The current supply chain crisis is causing goods to take up longer lengths of time to get to customers. The shortage of goods due to these delays is in part causing price increases for both businesses and consumers.

What is causing the crisis?

There’s plenty of blame being thrown around at who, or what, is causing the supply chain crisis. However, there are three main areas of focus that should be looked at when searching for the root of the problem: consumer spending, ships, and trucks.

Consumer spending

We’ve all spent a lot less money on services over the past 18 months and a lot more on goods. Think of that desk you ordered online or the birthday gifts you bought on Amazon. They’re all part of the massive increase in consumer spending that has driven up demand for limited-supply products. This is what started the ball rolling that led to the global supply chain catastrophe.

The supply chain crisis originated last spring when pandemic lockdowns led to drastic increases of consumer spending on goods, particularly online shopping. Consumers in lockdown were spending more from the comfort of their own homes on products instead of services. This raised demand for goods that are mainly manufactured overseas (or goods that are created from materials based overseas). Couple this with federal stimulus money being given to citizens, banks, and businesses, and you have trillions of new dollars flowing through the economy that are hunting for things to buy. In fact, online retail shopping is expected to top $200 billion for the first time in history this holiday season due to record demand.

The rise in demand for goods and raw materials also had to deal with a shortage of manufacturing capability. As the world spiraled into a recession when the pandemic began, corporate America predicted the pandemic would last for years. Vehicle manufacturers shut down the production of cars and car parts. Airlines decided they didn’t need to order more aircraft. Millions of employees in dozens of industries were laid off as executives went into survival mode.

Fortunately, economic recovery is moving faster than initially predicted, causing demand to continue to rise and the manufacturing sector to regain its pre-pandemic strength. Unfortunately, the ramped-up demand for goods conflicted with corporate expectations of the recession. Manufacturers are wishing they hadn’t canceled their orders for tech like microprocessors and semiconductors, which are now in short supply. These shortages have led to other shortages further down the supply chain, resulting in an increase in prices for what is still available to buy.

However, what is still available to buy is, for the most part, an ocean away.

Ships

Cargo ships can carry hundreds of steel containers filled with goods from around the world. However, goods stored in a container are goods not being purchased by customers. They need to get off of ships in order to help businesses make money. But getting access to port facilities is where the real problem lies: for much of the year 2021, between 70-90 cargo vessels at a time have waited in line to unload their cargo into the Port of Los Angeles. That number topped 100 ships in November. Other ports across the United States have been facing similar waiting issues.

What is causing ships to be unloaded so slowly? Two words: cargo containers. While these containers are essential for transporting goods and materials across the oceans, they also cause chokepoints in ports when they lie about empty. Too many of these empty containers are clogging up port space due to ships not wanting to carry unfilled cargo back across the seas.

Trucks

America has been facing a truck driver shortage for years. Trucking was one of the few industries that didn’t shut down during the early days of the pandemic, elevating drivers to hero status alongside healthcare workers and teachers. Yet with an increase in demand for goods comes an increase in the number of trucks and drivers needed to transport those goods to their destinations. The demand for drivers, however, is still not being met: the American Trucking Associations (ATA) estimates that the US is currently short 80,000 truckers.

Trucks deliver full containers from ports to customers across the nation and return empty containers to the port. But with ships unable (or unwilling) to transport empty containers back to overseas manufacturers, and with unloading docks running out of space to store unused containers, an increase in truck drivers would still not solve the issue of backed up ports. More truck chassis to carry full containers away would help alleviate the container issue, but that means someone besides the truck drivers themselves needs to find the time and money to purchase or manufacture more chassis to do this.

What problems is the crisis causing?

Notably, the crisis wouldn’t be a crisis if it wasn’t impacting customers everywhere. There are three main problems that supply chain holdups are dragging everyone into:

- Product Shortages

- High demand for manufactured goods puts a shortage on the materials it takes to make those goods

- Lack of product availability leads to scarcity; scarcity increases prices

- Price increases

- Some of these increases are the result of hidden surcharges such as “supply chain charges”

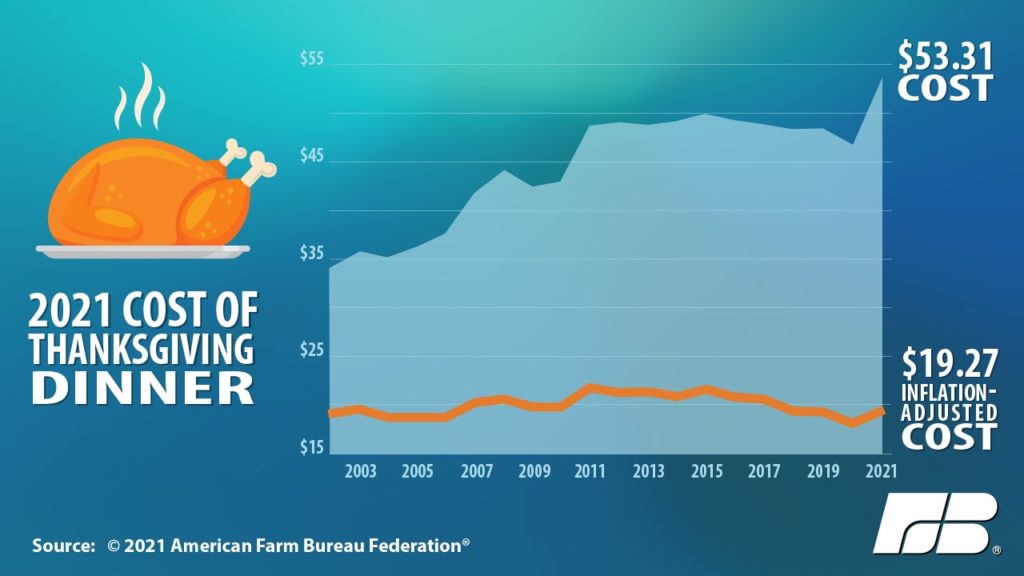

- Inflation also contributes to price increases so much so that Thanksgiving this year is nearly 15% more expensive than last year

- Slower shipping times

- An increase in demand slows the transit of goods

- Online shopping perks like “next-day shipping” can no longer guaranteed

From the corporate level to the consumer and everyone in between, the supply chain crisis hits hard. And just like all major economic woes, people are looking for someone to point fingers at.

Who should we blame?

So who is at fault for the supply chain crisis? The White House? Corporate America? Ordinary Americans? The answer is that everyone over the past few years has played a role in pushing the supply chains to where they are now. For example, despite spending a record $72.4 billion dollars online in October alone, consumers saw over 2 billion out-of-stock messages across virtual storefronts because we can’t stop buying more than what’s already being built and shipped. We’re all to blame for what has happened, and it’s up to all of us to learn the lessons of today for a better supply chain tomorrow.

What can we learn from the current supply chain crisis?

There are many issues still ongoing from the global supply chain crisis and inevitably there are more lessons to discover. However, there are a few things all businesses have been able to learn so far:

- Adjust customer expectations

- Many businesses used to pride themselves for having customer perks like next-day shipping or low prices. Those perks might not exist anymore. Getting your customers to stay loyal even without those benefits is key for any kind of supply chain disruption.

- Stay at Home: Obtain raw and finished materials from domestic sources

- Businesses that rely on materials across national borders or overseas are especially impacted by supply chain disruptions. Powerblanket is proud to source its materials right here in the United States, ensuring that we will be able to provide the heating products that people need throughout the year, despite supply chain issues.

- Agility: Have a plan for both major and minor disruptions

- Every level of enterprise must have a plan to deal with disruptions. What will you do if your supplier of a critical component has to shut down their factory? What if your employees can’t come to work for an extended period of time? Will you advise or mandate hygienic procedures to promote employee and customer health? How will you keep your customers engaged if you can’t keep up with demand?

We’re living through unprecedented times. The supply chain crisis definitely isn’t going away anytime soon. How businesses and individuals respond and evolve to meet these conditions will fundamentally change how we operate and get our products to consumers.

Your heating needs are essential to keeping your business running, whether it’s for process heating or winter operations. Powerblanket has striven to provide quality heating products while still keeping our short lead time commitment to customers. By using local talent and domestically-sourced materials, we’ve weathered the supply chain crisis and continue to serve your heating needs. Contact us at 833.485.0853 or [email protected] for heating help today.

Curious to see how Powerblanket can meet the unique needs of your industry?