Pipelines are the arteries of every industrial plant through which millions of dollars of liquids flow. Canadian oil producer, Cenovus, faced losing $8,000 a day if their pipes and instruments froze. To protect their instruments and keep the oil flowing in the harshest winter weather, they installed heat tracing all along the pipeline and throughout the process.

Electrical heat tracing calculation takes much planning to design a heat trace that generates the correct heat to maintain proper viscosity. This article will provide an overview of heat tracing systems and a guide to designing and installing a heat trace system. Let’s start with the basics.

What is Heat Trace?

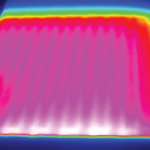

A heat trace can be an electrical resistance wire or tube circulating a heated liquid or steam, attached to the surface of a pipeline or tank, then wrapped with thermal insulation. It provides consistent heat and freeze protection for piping, valves, and instruments.

Heat trace systems maintain a specific temperature in piping and other vessels. They keep pipes and the fluids inside warm and flowing despite extreme temperatures.

Why Do You Need Heat Trace In Your Process Piping System?

Heat tracing is a cost-effective solution to maintain temperature in the pipeline. A heat tracing system can extend the life of the piping system and eliminate the need for costly maintenance and repairs.

They are critical for all industries that pump liquids in pipelines exposed to low or freezing ambient temperatures, such as food processing, pharmaceutical manufacturing, and oil and gas production. Heat tracing improves the system’s efficiency by decreasing the fluid’s viscosity and increasing its flow rate and thermal conductivity.

We also find heat trace systems in residential applications, such as hot water tanks and outdoor swimming pools. In other applications, heat cables prevent condensation or frost formation on surfaces.

How is Heat Tracing Done?

The design process begins with an evaluation of the system. Design engineers must factor in the temperature of the pipe’s contents, the ambient temperature, the heat loss rate, the pipe length, and the type of insulation. The pipe’s diameter and wall thickness also affect the heat trace’s capability.

Once the design team knows the heat requirement, they choose one of two heat trace cable types. The two most commonly used systems are self-regulating heat trace and constant wattage heat trace.

The self-regulating heat trace system uses a cable that varies its output based on the ambient temperature. Constant wattage heat trace systems use a cable with a heating element that remains at a set temperature throughout the system.

Heat trace systems must have the correct cable type, thermal insulation, and terminations to ensure safety and efficiency. The heat trace must be the right length, wattage, and ampacity for the environmental conditions.

The heat trace design team will create a detailed installation plan and a schematic system diagram. The schematic includes the location of the power outlets, the type of conduit, and the type of junction boxes. Once the engineers have the design data, they can order and install the correct heat trace system that achieves the desired results.

For more information, please review our article, How to install heat trace.

What Are The Types of Heat tracing?

The most common industrial heat tracing systems are:

- Electric Heat Tracing – Electric heat tracing systems use electrical resistance heating elements to maintain the desired temperature.

- Steam Heat Tracing – Steam heat tracing systems use steam pumped through tubing. The heat source can come from a separate boiler or waste heat from another process.

- Hot Water Heat Tracing – Hot water heat tracing systems use hot water as the heating source. Although less expensive, they have a temperature limit of 210°F (99°C). Also, the water cools as it flows through the system, making it difficult to maintain a consistent temperature in long pipe runs.

- Thermal Fluid Heat Tracing – Thermal fluid heat tracing systems use a heating media like oil to transfer heat to the piping system. These systems can provide higher temperatures and better control than water systems.

Electrical systems are the most common because they are easier to design, install, and control.

How Does a Typical Heat Trace Design Work?

A typical heat tracing design works by using a heating element attached to the pipe. The heating element can be embedded inside the pipe or wrapped around it.

The heat tracing system design includes the selection of the heat trace element, the power source, and the insulation material. The design data include the length of the piping system, pipe sizes, the desired temperature range, and the type of heating used.

The insulation material is critical to a properly designed system to reduce heat loss. It’s generally a closed-cell foam or a combination of foam and metal. The selection depends on the temperature range and the type of heat trace system.

Designing The Right Type of Heat Trace for Your Process

When selecting the correct type of heat trace, there are several design parameters to consider.

- Piping and equipment

- Desired temperature range

- Type of heat trace cable

- Insulation type

- Expected heat loss

- Expected Ambient temperatures

- Electrical supply

For a more detailed explanation, Thermon offers an FLX™ Self-Regulating Electric Heat Tracing Design Guide featuring an easy-to-use 5-step design.

We’ve already covered heat trace types and insulation. The next factor is heat loss.

Calculating Heat Loss

Determining heat loss is the first step when designing a heat trace system. To calculate it, we need to know the values for the following:

- Maintenance Temperature, Tm

- Minimum Ambient Temperature, Ta

- Location, Indoor/ Outdoor

- Wind Speed, if applicable

- Nominal Pipe/Tubing Size, DP

- Additional Safety Factor, if required

- Thermal Insulation Type and Thickness

Selecting the Proper Cable

Heat trace cables come in various configurations and temperature ratings. Variables depend on whether the piping is metal or non-metal, ambient temperatures, and length.

The primary types of cable include:

- Self-Regulating Low Temperature (Suitable for plastic pipes)

- Self-Regulating Medium Temperature

- H-Self-Regulating Low Temperature (Suitable for plastic pipes)

- H-Self-Regulating Medium Temperature

- Constant Wattage

- Mineral Insulated

Check with the manufacturer or use one of the guides to ensure the cable matches your application.

Heat Trace Calculator

To make it easier, use a heat trace calculator. It is software that takes the details of your process and calculates the system you’ll need, including the length, heat trace watts per foot, type of cable required, and heat loss. The calculator allows users to input all the variables and provides specific solutions for ordering the correct heat trace components.

Determine the Heat Trace Length

A heat trace length calculator can help to determine the length of the heat trace element required for a given piping system. It considers the piping system’s size, the desired temperature range, the type of heat trace system, and the insulation material.

The primary consideration is the pipe length, but you’ll need more cable for valves, supports, pumps, splice kits, etc. Other considerations include the available electrical supply, startup temperatures, and maximum circuit lengths of the cable.

Don’t Forget the Accessories

When calculating the cost and configuration of a heat trace, you must include accessories like a circuit fabrication kit, fixing tape, splices, and end seals.

For more detailed information, please read our article, Heat trace calculations.

Installing and Maintaining Your Heat Trace System

If you plan to install an electric heat trace system with in-house engineers, it is essential to read and understand the manufacturer’s instructions thoroughly. All installations and terminations must conform to your location’s National Electrical Code and other applicable national or local codes. Refer to page 13 of Thermon’s Heat Trace Design guide for proper installation tips.

After installation, it is advisable to test the system three times to ensure it’s working correctly.

Use Professionals To Guide You

Electric heat tracing systems are an essential part of any industrial process and can provide a cost-effective way to maintain the desired temperature of a piping system. There is a lot of data to compile and analyze before selecting the appropriate system.

Explore heat trace systems today for a reliable and cost-effective way to maintain the temperature. With the right design and installation, the Powertrace heat trace cable will keep you running at peak efficiency while avoiding costly repairs and downtime.

Don't let the cold weather stop your business. Powertrace heat trace cable will keep you running smoothly no matter how low the temperatures.