What do the copper, bronze, and iron ages have in common? Its heat, specifically, industrial process heat. Sometime between 5,000 to 7,000 years ago, someone figured out that fire could do more than cook dinner. It transformed raw materials and metal-bearing ores into copper and brass tools and weapons. The ancient discoveries of glass and ceramics were the products of high heat that have changed the way we live.

What is industrial heating? In basic terms, it’s applying heat to create something better.

Industrial processes consume an estimated 74% of the world’s energy, usually in the form of heat. Industrial process heat is a term that describes the thermal energy used directly to prepare or process the material for manufacturing.

The amount of heat depends on the industrial process. A European study estimated that:

- 30% of industrial heating applications required heat below 212°F (100°C)

- 27% between 212°F (100°C) and 750°F (399°C)

- 43% need heat above 750°F (399°C)

Industrial process heating is responsible for almost everything we take for granted, such as the components and glass in the device you are using to read this post. We’ll define the methods of industrial process heating applications, the industries that use them, and a source for industrial heaters if you need any.

If you need custom industrial heating solutions for your manufacturing or production process, Powerblanket engineers have expertise in designing safe, efficient heaters. Powerblanket heaters are engineered for reliability, safety, efficiency, and long life. We fully customize to meet your specific temperature, material compatibility, and hazardous location requirements.

The Definition of Industrial Process Heating

Industrial process heat is thermal energy used to produce, treat, or alter manufactured goods. Process heat provides the energy necessary for creating almost everything we use every day, such as cosmetics, textiles, cement, steel, composites, computer chips, plastics, and glass.

Processes at the low end of the thermometer, around 122°F (50°C), include space heating, cleaning, or washing operations. The food, textile, or chemical industries typically use higher operating temperatures between 212°F (100°C) and 482°F (250°C).

Metallurgical and ceramic processes require high heat. For example, 99.5% aluminum melts at 1,214°F (657 °C), and carbon steel begins melting at 1,425°F (734°C). Ceramics require kiln temperatures from 2,124°F to 2,264°F (1,162°C to 1,240°C).

Every industry requires process heating solutions. Here is a summary of the most well-known.

What Types of Industries Rely on Process Heat?

The industrial sector uses heat for many applications, including washing, cooking, sterilizing, drying, preheating boiler feed water, viscosity control, and many other processes. Some specific industries that require heat in one form or another are:

Gas Processing Industry – Heaters maintain the correct viscosity of petrochemical liquids and gasses when processing in extreme temperature conditions. Direct heating using immersion heaters delivers faster and more consistent heat dispersal inside tanks.

Chemical and Petrochemical Industries – Heaters are essential for distilling petroleum into its components. They use heat to combine chemicals into new ones or break them down into basic elements.

Power Generation – Heat drives the electrical generators that power our world. While the fuel or heat source can be different, the result is a steady supply of electrical power.

Aerospace – Composites are a core construction material for aircraft bodies, wings, and parts for satellites. Typical curing temperatures range between 250 °F and 350 °F (121 °C and 171 °C) inside autoclaves and curing ovens.

Food & Beverage – From brewing and distilling to canning and baking production lines, process heat is vital to all commercial F&B processes.

Agriculture – The types of heating found in agriculture include plant utility heating, tank and suction heating for ammonia tanks, and other chemicals, to name a few.

General Manufacturing – Almost any manufacturing sector requires heat at some point. Examples include molds and presses for plastic products, calendar rolls for drying textiles and papers, dryers, kilns, and air heating for turbines.

Industrial process heaters maintain the heat inside storage containers and tanks for optimal viscosity and flow. Process heating solutions include external heaters like blankets or internal suction and immersion heaters.

What are the Processes Involved in Heating?

There are four primary types of heat used in industrial processing:

- Fossil fuel

- Steam

- Electric

- Hydronic

Additionally, hybrid systems combine two heating methods such as fossil fuel and electric, to achieve the correct temperature.

Lower temperature systems typically use conduction or convection, whereas high-temperature processes use radiative heat transfer.

Fuel-based Process Heating Systems

The fuel for these systems will be natural gas, oil, or coal. The heat released from burning the fuel transfers directly or indirectly into the material. Indirect heating routes the heated gasses through burner tubes to the exhaust, keeping the gas separate from the material. The heat transfers across the tubes into the material, like a water heater.

Fuel-based process heating equipment includes furnaces, ovens, kilns, smelters, infrared heaters, and high-temperature generators.

Steam-based Process Heating Systems

Steam can transfer heat indirectly or get injected directly into the fluid in a process known as sparging. The water molecules in steam carry a large amount of energy and transfer it upon contact with colder molecules. Steam-based systems provide heat up to 338°F (170°C) and require low-cost fossil fuels to be economically competitive. Systems that produce both heat and electricity (Cogeneration) use steam-based heating.

Boilers, steam spargers, dryers, water, fluid, or slurry heaters are examples of steam-heated systems.

Electricity-based Process Heating Systems

Electricity-based heating can be a direct and indirect process. A direct method passes an electrical current through the material, where resistances create heat, like a toaster heating element. Another method is exciting the material’s molecules using electromagnetic radiation, like a microwave oven.

Indirect heating uses a heating element to transfer the heat by conduction, convection, radiation, or a combination of these into the material.

The best-known methods of electric-based heating systems are electric arc furnaces, infrared ovens, vacuum furnaces, and induction heating and melting.

Hydronic Process Heating Systems

A hydronic process heating system is a closed-loop heat exchange system like the radiator cooling system on a car. Steam or hot water circulates from a central boiler through heat exchangers like a radiator, where fans force the heated air into the space. It’s an efficient system for heating schools, offices, and other large areas because water conducts and transfers heat better than air.

Hybrid Process Heating Systems

Hybrid systems combine two process heating technologies to optimize thermal efficiency and reduce costs from wasted energy. These systems minimize energy consumption and increase production speed.

Operators can decrease energy costs by combining fuel-based and electric boilers. The boiler only uses electricity during off-peak hours to save costs. Another example is using a combination of electromagnetic (microwave) and convection heat to accelerate the drying process.

There are many industrial heating solutions, and they depend on the location of the heat source and the material to be heated.

Types of Electrical Process Heaters

There is an industrial heater for almost any application or location. Process heating with tank heaters includes immersion, circulation, and duct. Here is a breakdown of each type.

Immersion Heaters

The most common industrial process heaters are immersion heaters. They can provide up to 1,200°F (649°C) of heat to a process, and they are 100% efficient. They can heat tanks from 10 to 500,000 gallons. Immersion heaters come in four types:

-

- Flange Heaters – Flanged immersion heaters bolt directly to the side of a tank. They fit tank flanges up to 50in. NPS and provide reliable long-term heat within the tank.

- Over-the-Side Heaters – Over-the-side immersion heaters mount through the top of a tank or vessel. They provide heat for freeze protection, maintenance of viscous fluids, and other applications.

- Screw Plug Heaters – Screw plug immersion heaters are the go-to method for heating liquids and gasses. They can be mounted inside a tank using an NPT connection. Liquids are the most common products heated in screw plug applications.

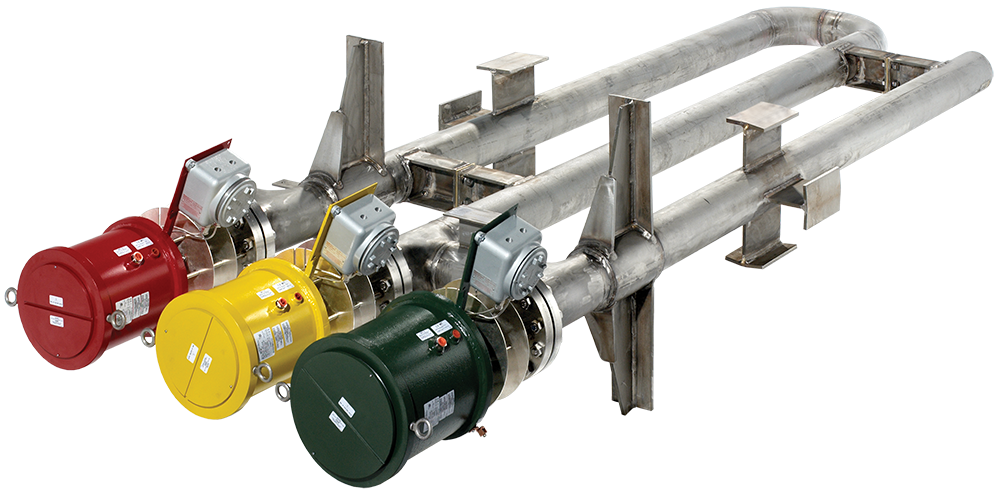

- Circulation Heaters – This type heats gas or liquids in line with the flow. They are capable of working in high pressures of up to 5,000 psi.

Depending on the application, housings can be stainless steel or carbon steel. Where the elements join in the terminal housing, they can be made liquid-tight or explosion-proof.

Circulation Heaters

Circulation heaters or inline heaters work in systems containing pressurized fluids such as steam, oil, or gasses. Mounting the heating elements inside an insulated steel vessel minimizes heat loss during the process flow while maintaining a highly efficient heat transfer rate.

They offer a custom heating solution for systems handling high-temperature industrial processes or corrosive products at specific flow rates and temperatures.

Industrial Duct Heaters

High-velocity fans draw ambient air into the chamber and pass over the heating elements, leaving the chamber at controlled temperatures as high as 1,200°F (649°C). They come in various sizes, power, and shapes, such as bottom mounted, flange-mounted, and round duct heaters.

Applications include primary and secondary heating, reheating, and multi-zone heating.

Explosion-Proof Heaters

Some processes handle volatile fumes or gasses where a spark from a motor can cause a disaster. Explosion-proof heaters keep people and materials warm without the risk of spark or fire. Also, flammable chemicals stored in totes and barrels require explosion-proof drum heaters. These flexible heaters maintain a constant temperature for sensitive materials.

The common denominator to most process heating is electricity. It’s a reliable source for generating heat. However, the immersion heating elements will require maintenance and eventual replacement.

Heating Element Maintenance and Replacement

Every heating element degrades over time either by continuous expansion and contraction or accumulation of buildup on the elements. In most cases, immersion heaters lose an estimated 30% of their output within five years.

Inspect every process heating element routinely per the manufacturer’s guidelines. Ordering replacement heaters and keeping them on standby will reduce potential downtime in the event of a failure.

Steady Heat In Hazardous Locations

Many industries work with potentially flammable and explosive liquids and gasses. The National Electrical Code (NEC) classifies these risks. A Class I hazardous location presents a risk from flammable gasses, vapors, and liquids. The danger in Class II areas is from combustible dust such as wheat or coal. Class III has ignitable fibers from fabrics or shavings that can catch fire if exposed to sparks or flame.

The division codes under these categories represent the hazard level. Div 1 means materials are explosive or hazardous.

Powerblanket offers safe industrial process heating solutions. We developed process heaters that comply with Class I Division 2 area certifications, and we can custom-build heaters for Class I, Div 1 areas, the most hazardous classification.

Custom Process Heating Solutions

Powerblanket provides custom heating solutions. We specialize in electric process heaters. Some of the industries we’ve helped include construction, chemicals, oil, natural gas, railroad, aerospace, semiconductors, and agriculture. Electric process heaters are a vital element in most industries. Our heaters provide stable process and temperature control for liquids and gasses.

Our PowerPro brand of electric process heaters has the highest quality materials for maximum efficiency, reliability, safety, and durability. We can replace any existing electrical heating system, inefficient or worn-out heaters, and update older systems. If parts storage is an issue, we can store your spare process heaters at our facilities and ship them to you as you need them.

If you have questions about process heating or temperature controls for your operation, call our engineers at 801.506.0198 or visit our contact us page.

When you need a custom temperature control solution, Powerblanket is the company to call. With over 30 years of experience, we can solve any heating dilemma you have.