Have you ever stopped to think about how often we make regular use of things we know very little about? For example, most of us can use computers proficiently, but how many of us actually comprehend the science behind their inner workings? Plenty of us have probably used epoxy too, but how many of us know what epoxy is made of?

Epoxy and Epoxy Resin

Perhaps the first thing to understand about this class of chemicals is this: there’s a difference between epoxy and epoxy resin. The difference is simple.

Epoxy

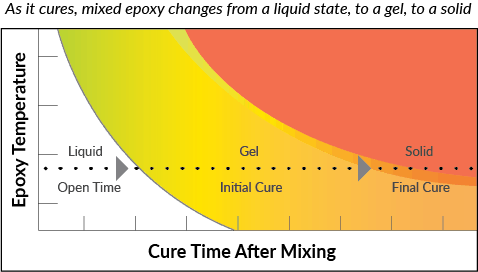

Epoxy is merely cured epoxy resin. In other words, epoxy resin is epoxy adhesive in its liquid form. For any epoxy, there are two primary parts to the equation: the resin and the curing agent. When the resin and the curing agent react together, the hardening process ensues.

Resin

The resin itself is made of bisphenol (and there is more than one type) and epichlorohydrin. The most common type of bisphenol is a combination of acetone and phenol. Maybe you’re asking yourself now: where on earth does phenol come from? Well, when it was first discovered, it came from coal tar, but nowadays, chemists extract it from petroleum (like so many other useful compounds). Now, as far as epichlorohydrin is concerned, well, it’s derived from something called allyl chloride, a chlorinated sub-chemical of propylene.

Epoxy is one of the best adhesives available for industrial uses. According to adhesives.org, epoxy resins, when cured, provide “rigid but tough bond lines and have excellent adhesion to metals. Chemical and environmental resistance is excellent. Most formulations have a paste consistency and can be applied by trowel or extruded as beads. They easily fill gaps and provide excellent sealing properties, particularly against harsh chemicals. They are often used as alternatives to welding and rivets.”

Curing

The curing agent plays a big role in how the epoxy turns out when it’s cured. There are numerous curing agent recipes, but one of the more common is a combination of amides and polyamides (which amounts to a variation of ammonia—the difference being the replacement of a hydrogen atom with a carbon + oxygen pair).

Temperature

Temperature can have a significant impact on epoxy curing. Heat will accelerate curing time, while cold will slow the curing process. However, cold temperatures are preferred when storing. This is due to epoxy resins becoming less effective after warming to room temperature.

In order to meet proper cure cycle requirements, many companies rely on extremely expensive ovens and high-temperature autoclaves. These types of facilities and tools are not only significant capital investments but are also expensive to operate. Additionally, these types of heating solutions require a significant amount of maintenance and calibration.

Epoxy curing solutions allow for economical and efficient heat application tailored to your unique epoxy curing needs. The latest heating blanket technology provides even heat distribution, tight temperature control, and insulated layers to prevent heat loss.

Heating Blankets

For lower-temperature epoxy cures, heat blankets provide a very reliable and efficient method of curing. Technology now exists in some heating blankets that provide:

- even heat distribution

- tight temperature control

- insulated layers to prevent heat loss waste

- programmable temperature controls

These heating blankets are very economical to operate. This is ideal for the epoxy curing process because it’s so critical to provide even, consistent heat to help the epoxy cure properly. Large operations with loads of cash to spend may like some of the standard heating solutions. However, most businesses operate on a budget and closely watch their expenses. These businesses will probably find some of the newer technology, like heating blankets, to be the ideal choice.

Powerblanket and Epoxy Curing

Maybe you feel like you better understand epoxy now, or maybe you don’t. Either way, you can still make use of the product for a variety of purposes. Whatever you use it for, there is one thing to remember: epoxy is temperature-sensitive. In fact, most epoxies cure best at temperatures far above the normal range for ambient air. Keeping epoxy curing at the ideal temperature becomes increasingly difficult when the needle drops. But, then again, that’s why epoxy-curing solutions exist.

Epoxy and resin curing blankets by Powerblanket can serve all your temperature control needs. From standard, fixed heating blankets to insulated cooling wraps, Powerblanket has got you covered. We even have custom solutions to match your individual requirements. Contact us at 855.977.9657 or [email protected] for more information.

Frequently Asked Questions

What are the ingredients of epoxy?

Epoxy is primarily made from the polymerization of epichlorohydrin with bisphenol-A, forming a resin that, when combined with a curing agent, creates a strong adhesive.

What are the raw materials of epoxy?

The main raw materials for epoxy include epichlorohydrin and bisphenol-A, though other materials like aliphatic glycols and phenol can be used for specialty resins.

Is epoxy resin just plastic?

Yes, epoxy resin is a type of plastic known as a thermoset, which means it becomes permanently hard and rigid once cured.

Where does epoxy come from?

Epoxy resins are typically derived from petroleum-based compounds, with the most common being a combination of epichlorohydrin and bisphenol-A.

Cure your epoxy resins faster and easier than ever before with Powerblanket.