HEATER CONTROL PANELS

Whether it’s monitoring alone, control and monitoring, or automation and monitoring, Powerblanket heating control panels bridge the gap between you and your equipment. PPowerblanket offers heater control panels that give you the power to automate, remotely control, and monitor your valuable materials and equipment. Our heater control panels include advanced features such as temperature control panels, heater control boxes, and heater switching systems to ensure optimal performance.

WHAT’S INSIDE THE FREE BROCHURE

Whatever the industry or application, Powerblanket heating control panels monitor and control your heating operations with simplicity, convenience, and precision.

- An overview of Powerblanket's innovative heating control panels

- Details on remote monitoring, precision control, and system compatibility

- Insights on custom configuration for specialized applications

- Analysis of how panels increase efficiency and deliver peace of mind

GET THE CUSTOM BROCHURE

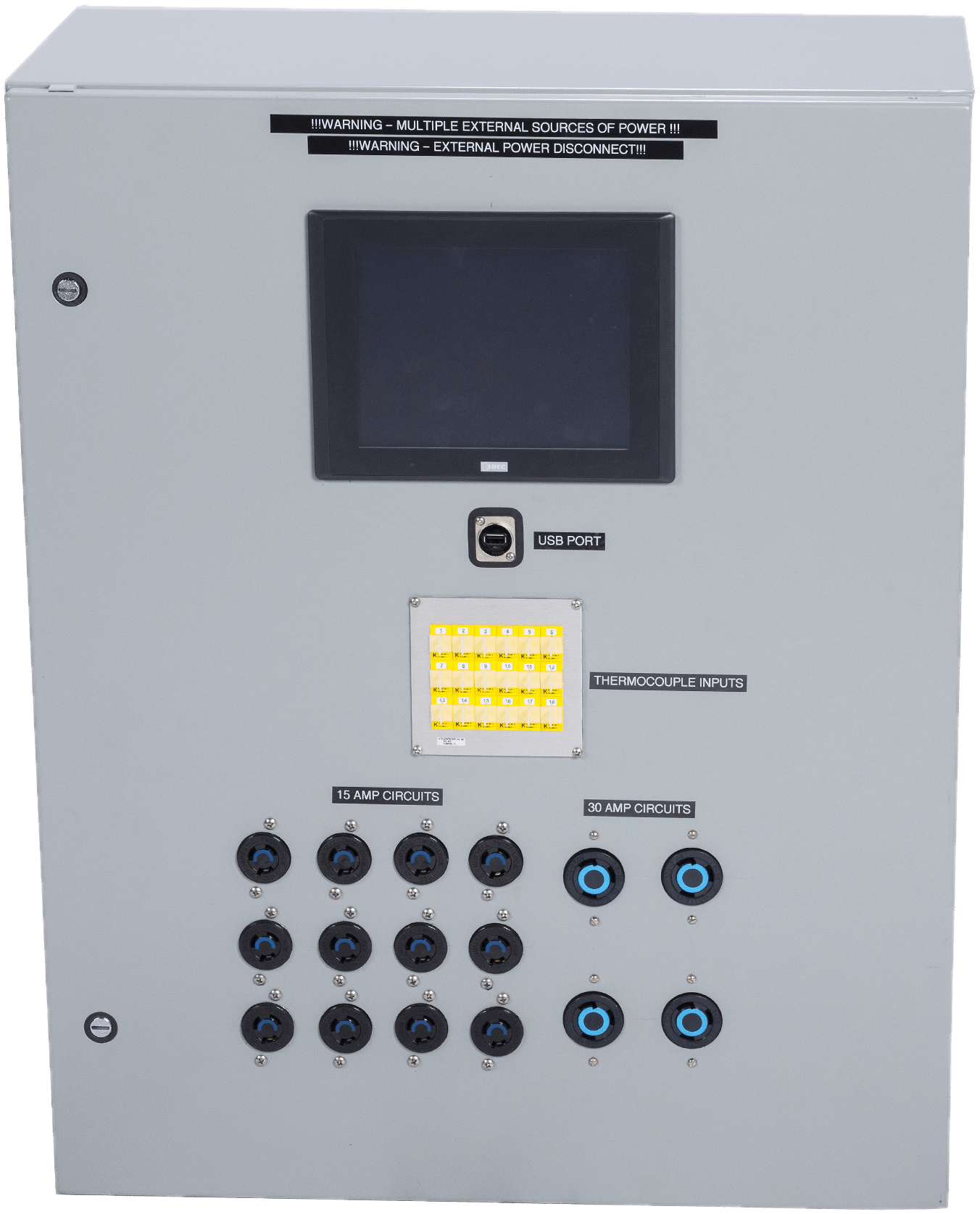

POWERBLANKET’S INNOVATIVE CONTROL PANELS

Powerblanket's innovative heating control panels allow you to easily and remotely manage those variables from the convenience of your smartphone, tablet, or computer. Whether you need to regulate external and internal variables associated with heating systems, Powerblanket’s heating control panels eliminate guesswork and risk, ensuring safe and efficient operation. These panels include electric heater control panels, temperature control panels, and control panel heaters that provide heater temperature control for a variety of applications.

- Simplicity

- Convenience

- Precision

INTELLIGENT TEMPERATURE MANAGEMENT

GREATER PEACE OF MIND

Systems can be setup for remote monitoring and control heating with alerts

INCREASED CONTROL

Ability to ramp up to a temperature at a specified rate, dwell at a specified temperature, and then switch off after a dwell period.

ACCESS ANALYTICS

Log data for record keeping or analysis, including temperature and relay state.

COMPATIBLE WITH MANY DEVICES

For use with many heating and cooling products.

CUSTOM CONTROL

Enhance heating and cooling products to achieve the exact performance needed.

Control Panel Applications

-

PowerTrace heat trace control panels offer precise control and monitoring for your heat trace systems, ensuring reliable performance and protection. Our heat trace control panels are available in pre-designed configurations for freeze protection or process maintenance, and can also be customized to meet specific needs. Choose from 120-600 VAC designs that feature integrated process control, ground fault monitoring, and remote or wireless capabilities for enhanced efficiency and safety.

Get a Control Panel Quote -

Optimize your operations with Powerblanket’s process heating control panels. These panels include advanced temperature controllers and heater control panels to regulate heating applications effectively. By using these solutions, you can focus on other aspects of your business while maintaining precise temperature control with electric heater control panels and temperature control boards.

Get a Control Panel Quote -

PowerBlanket offers a wide selection of temperature controllers and heating controllers that provide robust solutions for any application. Whether you need a simple thermostat, a temperature control panel, or an advanced temperature controller panel for voltage, current, and ground fault monitoring, we have you covered. Our options range from 120V to 480V, suitable for direct load or pilot duty, and are built to enhance your heat control systems.

Get a Custom Controller Quote

What is a Heat Trace Control Panel?

PowerTrace heat trace control panels consist primarily of an incoming power supply, a transformer (that if incoming power needs to be stepped down to a lower voltage for controllers), a main disconnect switch (to allow this power into the control panel) and a system or relays or breakers.

PowerTrace control panels are designed to operate one of two types of heat trace configurations: process maintenance (maintain) or freeze protection.

Process maintain applications require that a given temperature be maintained at the surface of the application. For example, a user may have several pipes filled with asphalt. Typical asphalt applications demand at least 350 F for a maintained temperature. In order to be controlled properly, each line will need it’s own sensor to verify that that individual line be kept at 350 F. Many sensors need to be brought back from the field to the line sensing or process maintenance electric control panel. Decisions in the controller are based on individual and independent needs of each circuit.

Freeze protection applications can be much more simple. For example, if you have 10 pipes that need to be protected from freezing, you could turn them all on at the same time when outdoor temps reach 40 F. One temperature sensor could be used to turn on all circuits at the same time.

What is a Process Heating Control Panel?

Powerblanket process heating control panels are some of the most reliable and innovative systems available today. Process heater control panels control a wide variety of applications. Whether you use your own system to control our panel with your Distributed Control System (DCS) or Programmable Logic Controller (PLC), use a local single channel PID controller, or need a PLC right on the panel, we have you covered. Units are available in voltages from 120 to 600 vac single or 3 phase, and common designs can have dozens of circuits and can handle wattages exceeding 5000kw.

Get a Custom Control Panel QuoteCustom Temperature Controllers

PowerBlanket temperature controllers provide a wide selection of simple and tough out of the box control solutions. When your process has one heat load to control, we can provide the best solution for your facility. From a simple single thermostat all the way to a controller that will monitor for voltage, current and ground fault-PowerBlanket has you covered. From 120V to 480v, direct load or pilot duty.

CUSTOM PROGRAMMABLE LOGIC CONTROLLERS (PLC)

Powerblanket designs and builds custom programmable logic controllers (PLC) for precise temperature control. PLCs are able to control key industrial and manufacturing processes and temperatures and provide ease of programming, a high level of reliability, and advanced diagnostics. Our custom temperature controller panels and heating controllers provide integrated analytics for monitoring temperature and relay states, enhancing the accuracy and reliability of your heating processes.

SMART CONTROLLERS: INDUSTRIAL INTERNET OF THINGS (IIOT)

Industrial Internet of Things (IIoT) refers to a wide range of controllers, sensors, and devices that are networked and connected together for industrial applications. Powerblanket has developed custom IIoT controllers that allow your personnel to monitor and control key industrial processes and critical temperatures from anywhere, giving you complete peace of mind.

Types of Temperature Control Panels

Powerblanket can design your custom temperature control system or temperature control board with a large selection of power controllers to ensure efficient use of power to your heating application. We provide control panels with the best power controls for your application. From mechanical contactors to the most modern solid state and silicone controlled power switching devices, Powerblanket has you covered.

CONTACTORS

Contactors are mechanical power switching devices. They are cheap and effective, but they have mechanical parts that can wear out over time. Contactors can also cause electric arcs when switching power, they can be affected by dirt, and they have a slow cycle time that can cause heaters to be damaged.

SOLID-STATE RELAYS (SSR)

Solid State Relays are semiconductor switches - solid-state switching devices that provide fast and variable proportional control of electric power for your control panel. Unlike mechanical relays or contactors, SSRs provide a high level of precision control over heaters, which can extend heater lifespan. They also switch quietly, and don’t have mechanical parts that wear out over time.

Frequently Asked Questions

Q: What is a heater control panel?

A: A heater control panel is a system comprising a temperature controller, temperature sensor, and a mechanism to relay power to the heater to create heat for a given process.

Q: What does a heater control switch do?

A: A heater control switch provides a set point or temperature that a process wants to be kept at. When temperatures go beneath that set point, the control switch asks the heater to turn on. When above it, it requires the heater to turn off.

Q: Where is the heater control switch?

A: A heater control switch is one of four main parts of the electric thermal loop: 1) the electric heater control switch or controller, 2) the device designed to switch power to the heater, 3) the sensor that verifies that heat is being applied, and 4) the heater itself.

Q: What is heater control?

A: Heater control is applying or removing heat in order to create a specific temperature.

Q: What is a temperature control panel?

A: A temperature control panel is a system that is designed to monitor and provide power to a heating system.

Q: Which is the best temperature controller?

A: The best temperature controller is a unit that will maintain heat in your system in the most reliable way.

Q: What device controls temperature?

A: Three main devices control temperature: 1) the sensor measuring the object being heated, 2) the controller that receives this signal from that sensor, and 3) the device that receives the signal from the controller allowing voltage to flow through the heater.

Q: How much is a temperature control?

A: Temperature controls can vary in price, from a simple thermostat at $10, all the way to hundreds of thousands of dollars for very complex process control systems.

Q: What is a heat trace controller?

A: A heat trace controller is a thermostat or simple control panel designed to monitor the object being heated by heat trace. When the object is too cool, the controller turns the heat trace on. When it is too hot, this controller turns the heat trace off. Often heat trace controllers will also provide ground fault protection and monitoring.

Q: How does a heat trace controller work?

A: A heat trace controller will use a set point as the basis for making decisions about when to turn a circuit of heat trace on or off. This can be done by a mercury filled thermostat, a digital thermostat, or a resistance temperature detector (RTD) which provide dependable outputs at specific temperatures. The controller recognizes these outputs from these sensors and will pull in or let go relays that allow voltage to flow into a given run of heat trace.

Q: Does self-regulating heat trace need a controller?

A: Self regulating heat trace only needs a controller if you want it to turn off once a preferred temperature is reached. For example, if you have a temperature that you want to use to keep a pipe from freezing, that temperature might have a set point of 40 F. Once you are higher than 40 F, there is no reason to keep the heat trace on, even if the self regulating heat trace reduces power as temperature increases. Even at 100 F, self regulating heat trace is still on and will pull amperage and power.