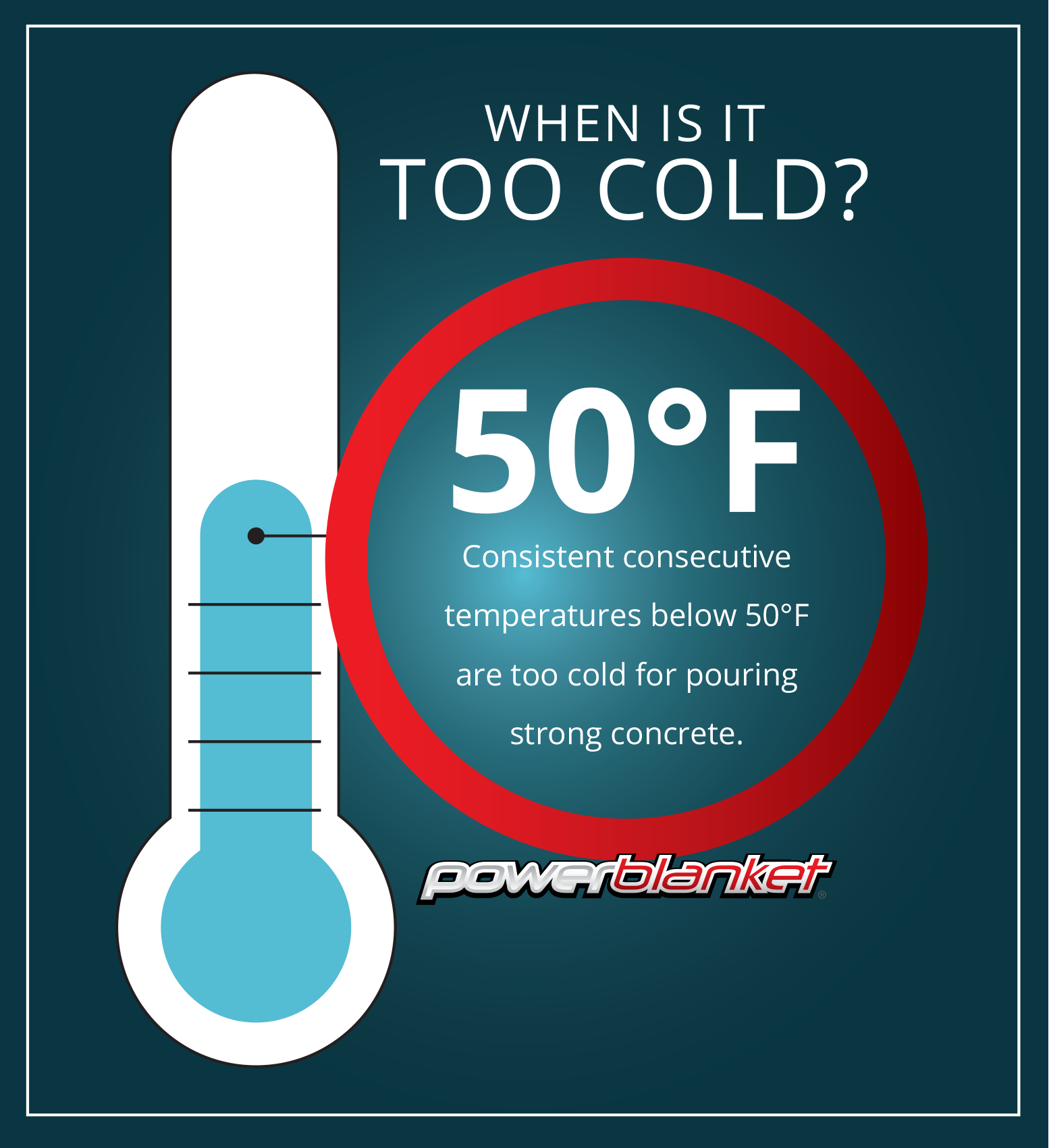

First, let’s define cold weather with respect to pouring concrete. Any time you have three consecutive days where the average daily temperature is less than 40°F, or if the temperature is lower than 50°F for less than half of any of the three days–that is undesirably cold for concrete. Pouring concrete in cold weather will have a detrimental affect on concrete curing for several reasons.

How Does Concrete Cure?

Concrete transforms from a liquid to a solid material through a chemical reaction. The speed of the reaction depends upon the temperature of the concrete. When the weather is warm, the reaction proceeds quickly. When it’s cold and the ground hasn’t been thawed, the reaction slows down. That’s the problem: the concrete needs to harden as rapidly as possible to resist pressures caused by water freezing within the concrete.

Slower Chemical Reactions

If the temperature is too cold, the concrete may not have reached a minimum strength of 500 psi soon enough to resist the effects of freezing temperatures. If your concrete isn’t protected with concrete curing blankets after it’s poured, it may cool too rapidly, slowing the chemical reaction.

Poor finishing techniques can also doom your slabs. Freshly poured concrete often bleeds. The water in the mix floats to the top, since it’s the lightest ingredient. Floating or troweling this water into the concrete weakens the top layer. Troweling the concrete too early can seal this bleed water just below the surface as well. If your slab is then exposed to freezing temperatures several days later, this water can freeze and fracture the top layer. Using a concrete curing blanket can eliminate the potential of freezing.

Read how Powerblanket solved concrete issues at the Statue of Liberty.

Concrete Can Be Successfully Poured in Cold Weather

How to avoid a bad concrete pour:

- Never pour concrete on frozen ground, snow, or ice.

- Be sure to order air-entrained concrete. Request a heated mix or order 100 lbs of extra cement for each cubic yard of concrete. This extra cement helps develop early strength.

- Be sure the concrete is ordered with a low slump (drier mix). This minimizes bleed water.

- After the final finish is completed, cover the concrete with a concrete curing blanket. The heated concrete blanket will prevent freezing and keep the concrete at an optimal curing temperature.

- After about three days, remove heated concrete blankets to allow the concrete to air dry.

Powerblanket Concrete Curing Blankets

If you use Powerblanket Concrete Curing Blankets to pour in cold weather, your cement will cure 2.8 times faster than with conventional insulated blankets. Time and convenience are critical factors when planning out a project in the winter, and Powerblanket has you covered. Our goal is to provide solutions to problems, and give you total temperature control over every process and aspect of your business.

We Solve Problems

From drum and barrel heaters to pipe wraps and snow melting mats, Powerblanket is dedicated to helping your business grow, saving jobs, and improving your bottom line. Whether you need to extend the pouring season, or you are trying to survive an early winter, know that you have total temperature control with Powerblanket.

Cure your concrete faster and better in cold weather conditions with Powerblanket.